Industrial PCAP touch screen technology

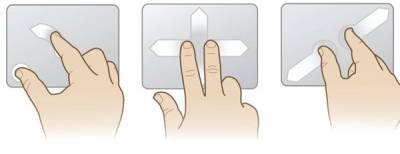

The PCAP touch technology allows the electrode layers to be fully protected by glass plates since direct contact between the finger and electrodes is not needed to trigger the touch functionality.

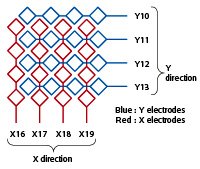

The capacitive coupling between the horizontal x electrodes (red) and the vertical y electrodes (blue) are scanned to detect touch.

| Edge bonding:

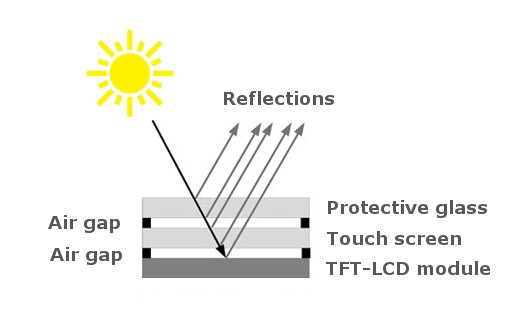

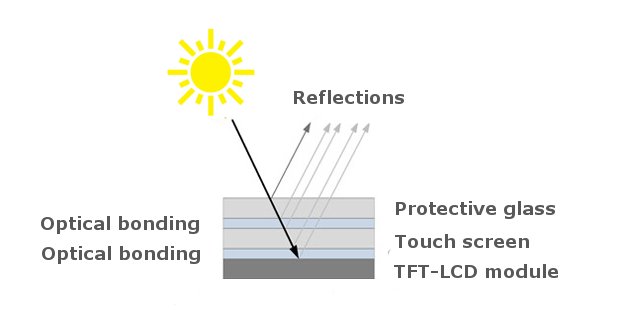

When light travels through material layers and pass from one material to another with different refractive index (for instance glass to air or air to glass) reflections are generated. |

| Optical bonding:

The refractive indexes of the glass and adhesive are matched to reduce reflections and increase image quality. |

Questions about PCAP Touch? Contact us! |